High Frequency Eddy Current Heating

Eddy current is defined as the induced current in a conducting coil when a magnetic flux is allowed to flow through it or in other words, it is the induced current in a conducting body due to a change in magnetic flux. The eddy current definition can be explained as an important nature of a solid conducting body.

Eddy Currents:

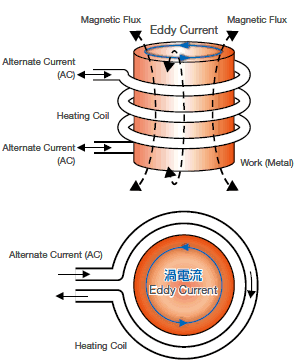

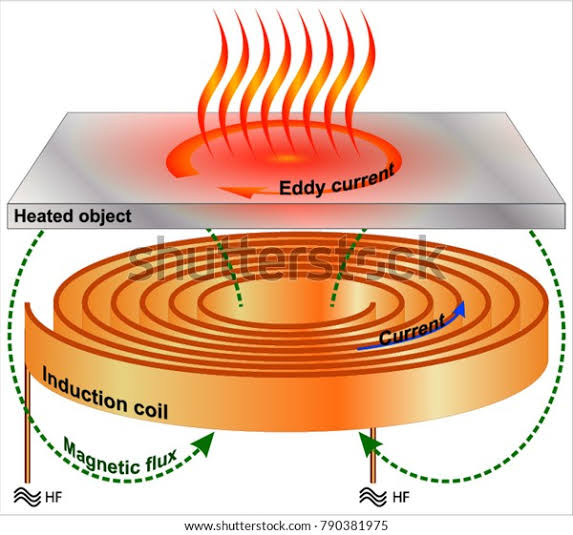

When a conductor is placed in a changing magnetic field, circular currents, known as eddy currents, are induced within the conductor.

Induction Heating:

Induction heating leverages this principle by using a high-frequency alternating current (AC) to generate a rapidly changing magnetic field.

Joule Heating:

As the eddy currents flow through the resistance of the material, they generate heat through Joule heating (also known as resistive heating).

Applications:

Induction heating finds applications in various fields, including:

Induction hardening: Heating specific areas of metal parts to increase surface hardness.

Induction forging: Heating metal parts to a desired temperature for forging.

Induction melting: Heating metals to a liquid state for casting or other processes.

Induction cooking: Heating cookware using induction heating.

Frequency Range:

Induction heating typically uses frequencies ranging from 100 kHz to 10 MHz.

Skin Effect:

At high frequencies, eddy currents tend to flow primarily on the surface of the conductor, a phenomenon known as the skin effect.

Laminations:

In devices like transformers and motors, where eddy currents can cause energy loss, thin sheets of magnetic material (laminations) are used to reduce their effects.

Non-conductive magnetic materials:

Inductors and transformers used at higher frequencies often have magnetic cores made of nonconductive magnetic materials such as ferrite or iron powder held together with a resin binder.

By JJR.

Comments

Post a Comment